At ValidExamDumps, we consistently monitor updates to the APICS CPIM-8.0 exam questions by APICS. Whenever our team identifies changes in the exam questions,exam objectives, exam focus areas or in exam requirements, We immediately update our exam questions for both PDF and online practice exams. This commitment ensures our customers always have access to the most current and accurate questions. By preparing with these actual questions, our customers can successfully pass the APICS Certified in Planning and Inventory Management (CPIM 8.0) exam on their first attempt without needing additional materials or study guides.

Other certification materials providers often include outdated or removed questions by APICS in their APICS CPIM-8.0 exam. These outdated questions lead to customers failing their APICS Certified in Planning and Inventory Management (CPIM 8.0) exam. In contrast, we ensure our questions bank includes only precise and up-to-date questions, guaranteeing their presence in your actual exam. Our main priority is your success in the APICS CPIM-8.0 exam, not profiting from selling obsolete exam questions in PDF or Online Practice Test.

An example of a cradle-to-cradle sustainability model would be:

A cradle-to-cradle sustainability model is a design concept that aims to create products that can be reused or recycled indefinitely, without generating any waste or pollution. It mimics the natural cycles of nature, where everything is a nutrient for something else. A cradle-to-cradle model differs from a cradle-to-grave model, which follows a linear path of production, consumption, and disposal.

Option B is an example of a cradle-to-cradle model, because the paper waste from the coffee shop is collected and recycled by a supplier, who then provides new paper products to the coffee shop. This creates a closed loop of material flow, where nothing is wasted and the paper is continuously reused.

Option A is not a cradle-to-cradle model, because the laundry service does not reuse or recycle the baby clothes. It only cleans and delivers them, but does not prevent them from eventually ending up in the landfill.

Option C is not a cradle-to-cradle model, because the company does not ensure that the wood it uses is from sustainable sources, or that the products it makes can be easily disassembled and recycled. It also does not consider the environmental impacts of transporting the wood from different locations.

Option D is not a cradle-to-cradle model, because the bank does not directly influence the design or production of the products that the firms use. It only provides financial incentives for them to adopt more sustainable practices, but does not guarantee that they will follow a cradle-to-cradle approach.

* Cradle-to-Cradle for Sustainable Development: From Ecodesign to Circular Economy

* Cradle to Cradle -- Sustainability Guide

An example of an assignable cause of variation in process performance is:

An assignable cause of variation is a source of variation that is intermittent, not predictable, and identifiable. It is also called a special cause of variation. An assignable cause of variation affects the process performance in an unexpected and non-random way, and it can be eliminated or controlled by finding and correcting the specific cause1. An example of an assignable cause of variation in process performance is incorrect setup of a machine by the operator. This means that the operator did not follow the standard procedure or specification for setting up the machine, which may result in defective or nonconforming products or materials. This cause of variation can be identified and corrected by checking the setup instructions, training the operator, or implementing a setup verification system23. Reference: 1 Assignable Cause - isixsigma.com 4 2 Process Capability Analysis - an overview | ScienceDirect Topics 5 3 CPIM Exam Reference - Association for Supply Chain Management 1

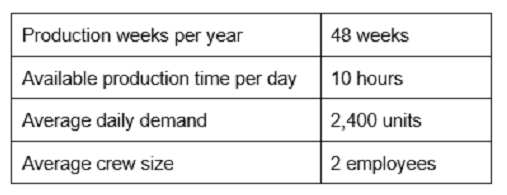

Given the following data, calculate the appropriate takt time:

Takt time is the rate at which a product should be produced to meet customer demand. It is calculated by dividing the available production time by the customer demand. In this case, the available production time is 10 hours per day, and the customer demand is 2,400 units per day. Converting 10 hours to minutes gives us 600 minutes of production time per day. So, takt time = 600 minutes / 2400 units = 0.25 minutes per unit. However, this is not one of the answer choices, so we need to look for more information or context.

According to the CPIM Part 1 Study Guide, takt time is usually rounded up to the nearest whole number to allow for some buffer time and to simplify the calculation. Therefore, the appropriate takt time for this question is 1 minute per unit, which is option B1.

Which of the following benefits typically will be realized when switching from a functional to a cellular layout?

A cellular layout is a workplace organization in which processes are organized by the product or product family, rather than by the type of work (function). A cellular layout consists of cells, which are groups of machines or workstations that are located close to each other and perform all the operations required for a product or product family. A cellular layout has several advantages over a functional layout, such as reduced material handling, improved quality, increased flexibility, and enhanced employee involvement. One of the main benefits of a cellular layout is that products will have faster throughput. Throughput is the rate at which products are produced and delivered to the customers. A cellular layout can increase the throughput by reducing the travel distance, the waiting time, and the setup time for the products. A cellular layout can also improve the production flow, the synchronization, and the visibility of the products. The other options are not correct, as they are not the typical benefits of switching from a functional to a cellular layout, but rather possible drawbacks or trade-offs of switching from a functional to a cellular layout:

Equipment utilization will be higher: This is unlikely to be true, as a cellular layout may result in lower equipment utilization than a functional layout. Equipment utilization is the ratio of the actual output of a machine to its maximum possible output. A cellular layout may reduce the equipment utilization by dedicating some machines to specific products or product families, which may limit the sharing of machines across different products or product families. A cellular layout may also reduce the equipment utilization by balancing the workload among the machines within a cell, which may prevent some machines from operating at their full capacity.

Quality inspections will be reduced: This may or may not be true, depending on the quality level and the quality control system of the production process. A cellular layout may reduce the quality inspections by improving the quality of the products, as the workers in a cell are more responsible, skilled, and empowered to perform the operations and to detect and correct the defects. However, a cellular layout may also increase the quality inspections by requiring more frequent and rigorous checks of the products, as the products move from one cell to another or from one stage to another.

Capital expenditures will be reduced: This is unlikely to be true, as a cellular layout may result in higher capital expenditures than a functional layout. Capital expenditures are the costs of acquiring or upgrading the fixed assets, such as machines, equipment, or facilities. A cellular layout may increase the capital expenditures by requiring more machines or equipment to create the cells, especially if the machines or equipment are specialized or customized for specific products or product families. A cellular layout may also increase the capital expenditures by requiring more space or facilities to accommodate the cells, especially if the cells are dispersed or isolated from each other.Reference:

[CPIM Part 2 - Section B - Topic 4 - Sustainability]

Cellular Manufacturing: Definition, Examples & Advantages --- Katana

Cellular or Functional Layout? - IGI Global

What is cell layout? - Studybuff.com